As an Amazon Associate, I earn from qualifying purchases

Introduction to Air Compressors

How to Use a Air compressors are versatile machines that play a crucial role in various industries and applications. They are designed to convert power into potential energy stored in pressurized air. This pressurized air can then be used to power pneumatic tools, machinery, and equipment, making tasks more efficient and convenient.

How to Use a Air Compressor

1. Safety Precautions and Guidelines for Using a Air Compressor: How to Use a Air Compressor Safely

How to Use an air compressor can be a convenient and efficient way to power various tools and equipment. However, it is important to prioritize safety when operating an air compressor to prevent accidents or injuries. Safety Precautions to Remember:

- Read the Manual: Before using an air compressor, thoroughly read and understand the manufacturer’s manual. Familiarize yourself with the specific safety guidelines, operating instructions, and maintenance procedures.

- Wear Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, such as safety goggles, gloves, and hearing protection, when operating an air compressor. PPE helps protect you from flying debris, noise, and potential hazards.

- Maintain Proper Ventilation: Ensure that the area where the air compressor is being used has adequate ventilation. Good airflow helps dissipate heat and prevents the buildup of fumes or hazardous gases.

- Check for Leaks: Before starting the compressor, inspect all connections, hoses, and fittings for leaks. Even a small leak can compromise the efficiency and safety of the system. Address any leaks promptly.

- Securely Position the Compressor: Place the air compressor on a stable and level surface to prevent it from tipping over during operation. Secure it with appropriate restraints if necessary.

- Monitor Air Pressure: Set the appropriate pressure level on the compressor according to the tool or equipment being used. Avoid exceeding the maximum pressure rating recommended by the manufacturer.

- Use Properly Rated Tools and Accessories: Ensure that the tools and accessories you connect to the air compressor are designed for the specific pressure and capacity of the system. Using incompatible tools can lead to accidents or damage.

- Release Pressure before Maintenance: Before performing any maintenance or making adjustments to the compressor, always release the pressure in the system and unplug the unit. This prevents accidental startups or releases of compressed air.

- Regularly Inspect and Maintain the Compressor: Follow the recommended maintenance schedule provided by the manufacturer. This includes regular oil changes, filter replacements, and inspections of hoses, connectors, and other components.

- Disconnect Power when Not in Use: When the air compressor is not in use, unplug it from the power source and ensure the pressure is fully released from the system. This prevents accidental startups and potential hazards.

2. Understanding Air Compressor Components

An air compressor is a versatile and essential tool used in various industries and applications. To effectively utilize and maintain an air compressor, it is important to have a good understanding of its key components. Here are some important air compressor components to familiarize yourself with:

- Compressor Unit: The compressor unit is the heart of the air compressor system. It is responsible for compressing air and delivering it at the desired pressure. The unit typically consists of a motor, pump, and compression chamber.

- Pressure Gauges and Controls: Pressure gauges are used to monitor the pressure levels inside the compressor and the air tank. They provide vital information for safe and efficient operation. Controls, such as pressure switches and regulators, allow you to adjust and maintain the desired pressure.

- Air Tanks: Air tanks store the compressed air and act as a reservoir. The tank’s capacity determines the amount of compressed air available for use. It is important to regularly check the tank’s condition, ensure it is properly maintained, and drain any accumulated moisture.

- Air Filters and Regulators: Air filters help remove contaminants, such as dust and debris, from the compressed air before it reaches the tools or equipment. Regulators control the air pressure flowing through the system, allowing you to adjust it as needed for different applications.

- Hoses and Connectors: Hoses and connectors are crucial for transferring the compressed air from the compressor to the desired tool or equipment. It is important to choose the appropriate type of hoses and connectors that are compatible with the air compressor system and the tools being used.

3. Setting Up an Air Compressor

Setting up an air compressor properly is essential for safe and efficient operation. Whether you are using an air compressor for professional purposes or at home, here are the steps to follow when setting it up:

- Choose the Right Location: Select a well-ventilated area with enough space to accommodate the air compressor and allow for proper airflow. Ensure the surface is stable, level, and free from any potential hazards.

- Read the Manual: Familiarize yourself with the manufacturer’s instructions and safety guidelines by reading the manual thoroughly. Each air compressor may have specific requirements and recommendations.

- Electrical Connection: Check the voltage requirements of your air compressor and ensure that the power source matches. Use a grounded electrical outlet and, if necessary, use an appropriate extension cord that can handle the power load.

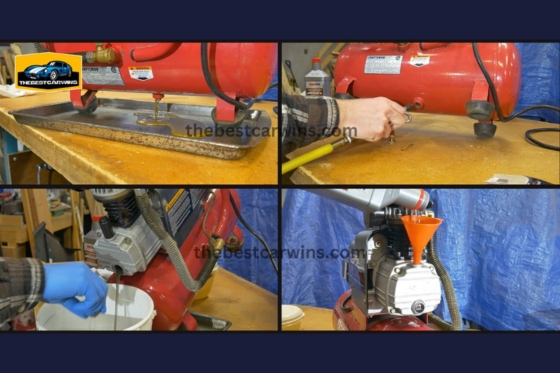

- Check Oil Level: For oil-lubricated compressors, check the oil level before starting. Follow the manufacturer’s instructions on the type and amount of oil required. Monitor the oil level and make adjustments or perform oil changes as necessary.

- Check the Air Filter: Inspect the air filter and clean or replace it if necessary. A clean air filter ensures proper air intake and helps prevent damage to the compressor.

- Adjust Pressure Settings: Set the desired pressure level on the compressor according to the tool or equipment you will be using. Refer to the manufacturer’s guidelines or the pressure requirements of the tools.

- Connect the Air Hose: Attach one end of the air hose to the compressor’s air outlet, ensuring a secure connection. The other end of the hose will be connected to the tool or equipment you plan to use.

- Test for Leaks: Before starting the compressor, carefully inspect all connections, hoses, and fittings for any signs of leaks. Address any leaks promptly to ensure optimal performance and safety.

- Power On and Prime: Turn on the compressor and allow it to build pressure. If it is an oil-lubricated compressor, allow it to run for a few minutes to prime the system and distribute oil throughout the components.

- Monitor Operation: Keep an eye on the pressure gauges and listen for any unusual sounds or vibrations. Ensure that the compressor operates within the recommended pressure range and that it maintains a steady supply of compressed air.

4. Operating an Air Compressor Safely and Effectively

Operating an air compressor requires proper knowledge and adherence to safety guidelines to ensure both personal safety and efficient performance. Here are some important tips for operating an air compressor safely and effectively:

- Read the Manual: Familiarize yourself with the manufacturer’s instructions and safety guidelines by thoroughly reading the manual. Each air compressor may have specific operational procedures and safety precautions.

- Personal Protective Equipment (PPE): Always wear the appropriate personal protective equipment, including safety goggles, gloves, and hearing protection. PPE safeguards against potential hazards, such as flying debris and loud noise.

- Start-Up Procedures: Before starting the compressor, ensure all valves are in the closed position and all switches are in the off position. Follow the recommended start-up procedures provided by the manufacturer.

- Monitor Pressure: Regularly check the pressure gauges to ensure the compressor operates within the recommended pressure range. Avoid exceeding the maximum pressure rating specified by the manufacturer.

- Proper Tool Selection: Use tools and accessories that are compatible with the air compressor’s capacity and pressure requirements. Using tools that exceed the compressor’s capabilities can lead to equipment failure or accidents.

- Use the Correct Connectors: Connect hoses and fittings securely to the compressor and tools. Use the appropriate connectors to ensure a proper and leak-free connection.

- Monitor Air Quality: If the compressed air is used for applications where air quality is crucial, such as painting or sandblasting, use appropriate filters and regulators to remove moisture, oil, and contaminants.

- Allow for Cooling Time: If your compressor has been running for an extended period or under heavy load, allow it to cool down before shutting it off. This helps prevent damage to the components and extends the compressor’s lifespan.

- Shut Down Properly: When shutting down the compressor, close all valves and switches, and release any pressure in the system. Unplug the compressor from the power source and store the hoses and accessories properly.

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule, which may include tasks like changing oil, cleaning filters, inspecting hoses and fittings, and checking for any signs of wear or damage.

5. Utilizing Air Tools and Accessories with an Air Compressor

Air compressors are versatile tools that can power a wide range of air tools and accessories for various applications. Understanding how to properly utilize these tools and accessories with your air compressor can enhance productivity and efficiency. Here are some essential tips for utilizing air tools and accessories effectively:

- Choose the Right Tools: Select air tools that are suitable for your specific application. Consider factors such as tool size, required pressure, and airflow capacity. Using the correct tool for the job ensures optimal performance and prevents unnecessary strain on the compressor.

- Connectors and Fittings: Ensure that the connectors and fittings used to attach air tools are compatible with your air compressor’s specifications. Check for proper thread size, type, and connection method to ensure a secure and leak-free connection.

- Regulate Air Pressure: Adjust the air pressure to match the requirements of the air tool being used. Most air tools have recommended operating pressure ranges specified by the manufacturer. Properly regulating the air pressure ensures safe and efficient operation.

- Lubrication: Some air tools require regular lubrication to maintain their performance and extend their lifespan. Refer to the manufacturer’s instructions to determine the appropriate lubrication method and schedule for each tool.

- Use Filters and Regulators: Install appropriate air filters and regulators to maintain air quality and regulate pressure. Filters help remove moisture, oil, and contaminants from the compressed air, preventing damage to air tools and ensuring optimal performance.

- Safety Precautions: Always follow safety guidelines when using air tools and accessories. Ensure you are equipped with suitable personal protective equipment, including safety goggles, gloves, and ear protection. Securely fasten workpieces and ensure a stable work environment.

- Proper Handling and Storage: Handle air tools with care and store them in a clean and dry environment when not in use. Avoid dropping or mishandling tools, as this can damage internal components and compromise their functionality.

- Regular Maintenance: Conduct regular maintenance of air tools and accessories as recommended by the manufacturer. This may include cleaning, lubrication, and inspection for any signs of wear or damage. Proper maintenance ensures optimal performance and prolongs the lifespan of your tools.

- Training and Education: If you are new to using specific air tools or accessories, seek proper training and education to understand their operation and safety precautions. Familiarize yourself with the tool’s features, functions, and any specific operating instructions.

- Read User Manuals: Always read and follow the user manuals provided by the manufacturers for both your air compressor and air tools. These manuals provide important information on proper usage, maintenance, and safety guidelines specific to each tool.

6. Maintenance and Troubleshooting Tips for Air Compressors

Regular maintenance and troubleshooting are essential for keeping your air compressor in optimal working condition. By following these maintenance and troubleshooting tips, you can extend the lifespan of your compressor and ensure its reliable performance. Here are a few crucial guidelines to take into account:

Regular Cleaning: Keep your air compressor clean and free from dust, debris, and oil buildup. Use a soft cloth or brush to wipe down the exterior surfaces and remove any accumulated dirt. Follow the manufacturer’s recommendations to clean or replace air filters regularly and ensure optimal airflow.

Check Oil Levels: Check the oil levels in your compressor regularly and top up or change the oil as needed. Refer to the manufacturer’s guidelines for the recommended oil type and maintenance schedule. Clean or replace oil filters as required to prevent contamination.

- Inspect Belts and Hoses: Regularly inspect the belts and hoses for any signs of wear, cracking, or leakage. Replace damaged or worn-out belts and hoses promptly to avoid sudden failure and potential accidents.

- Drain Moisture: Air compressors accumulate moisture over time, which can lead to corrosion and reduced performance. Drain the moisture from the air tank regularly by opening the drain valve. Follow the manufacturer’s instructions for the recommended frequency of moisture draining.

- Check Pressure Gauges: Ensure that the pressure gauges on your air compressor are functioning accurately. If you notice any discrepancies or abnormalities, consider calibrating or replacing the gauges as necessary.

- Tighten Connections: Periodically inspect and tighten all the connections, including fittings, hoses, and couplings. Loose connections can cause air leaks, reducing the compressor’s efficiency and performance. Verify that all connections are tightly secured and completely leak-free.

- Lubricate Moving Parts: Lubricate the moving parts of your air compressor as recommended by the manufacturer. Proper lubrication reduces friction, extends the life of the components, and helps the compressor operate smoothly.

- Address Unusual Noises or Vibrations: If you notice any unusual noises or vibrations coming from your air compressor during operation, investigate the cause immediately. These could be signs of mechanical issues or loose components that require attention. Consult the manufacturer’s manual or seek professional assistance if needed.

- Store in a Suitable Environment: When not in use, store your air compressor in a clean and dry environment, away from extreme temperatures, moisture, and corrosive substances. This helps prevent damage to the compressor and prolongs its lifespan.

- Follow Manufacturer’s Guidelines: Always follow the maintenance guidelines provided by the manufacturer. They are designed to ensure optimal performance and safety. Adhering to these guidelines will help you maintain your air compressor effectively.

7. Storage and Transportation of an Air Compressor

Proper storage and transportation of an air compressor are crucial to maintain its condition and ensure safe handling. Whether you need to store the compressor for an extended period or transport it to a different location, following these guidelines will help protect your investment. Here are some essential tips for storing and transporting an air compressor:

- Clean the Compressor: Before storing or transporting the air compressor, ensure it is clean and free from dirt, dust, and debris. Wipe down the exterior surfaces using a soft cloth or brush. Cleaning the compressor prevents any contaminants from affecting its performance and longevity.

- Secure the Power Source: Disconnect the power source from the compressor before storing or transporting it. This prevents any accidental activation and ensures safety during handling.

- Release Pressure: Before storing or transporting, release all the pressure from the air tank. Open the drain valve and let the compressed air escape. This step eliminates any potential hazards and protects the integrity of the tank.

- Protect from Moisture: Moisture can cause corrosion and damage the internal components of the air compressor. Store the compressor in a dry location, away from direct exposure to moisture. Consider using a dehumidifier or moisture-absorbing products to maintain a dry environment.

- Choose an Appropriate Storage Space: Select a storage area that is well-ventilated, clean, and free from extreme temperature fluctuations. Avoid storing the compressor in areas prone to excessive heat, cold, or humidity. Ideally, keep it in a dedicated storage room or a well-protected garage.

- Secure the Compressor: Use straps or other securing mechanisms to hold the compressor in place during transportation. This prevents it from shifting or falling over, which can cause damage.

- Protect from Physical Damage: Place the compressor in a sturdy and protective case or cover to shield it from potential impacts, scratches, and dust during transportation or storage. Consider using foam padding or cushioning materials for added protection.

- Transport with Care: When transporting the air compressor, handle it with care to avoid jolts, vibrations, or rough movements. If using a vehicle, ensure it is properly secured and positioned to minimize excessive shaking or bouncing.

- Follow Manufacturer’s Guidelines: Consult the manufacturer’s guidelines specific to your air compressor model for any additional storage or transportation instructions. They may provide valuable insights on best practices and precautions tailored to your equipment.

- Regular Inspection: Periodically inspect the stored or transported air compressor for any signs of damage, leaks, or other issues. Address any problems promptly to prevent further damage and ensure the compressor’s optimal performance.

Conclusion and Final Thoughts

Using an air compressor can greatly enhance your productivity and efficiency in various applications, from inflating tires to powering pneumatic tools. However, it’s essential to prioritize safety, understand the components, and follow proper operating procedures to ensure optimal performance and prevent accidents.

In this guide, we covered a range of topics related to air compressor usage, including safety precautions, understanding components, setting up and operating the compressor, utilizing air tools and accessories, maintenance and troubleshooting tips, and storage and transportation guidelines.

Safety should always be the top priority when using an air compressor. By adhering to essential safety guidelines, wearing appropriate personal protective equipment (PPE), ensuring proper ventilation, and following electrical safety measures, you can minimize the risk of accidents and injuries.

Understanding the components of an air compressor is crucial for its efficient and effective operation. From the compressor unit itself to pressure gauges, air tanks, filters, regulators, hoses, and connectors, knowing how these components function and how to maintain them will contribute to the longevity and performance of your air compressor.

Properly setting up the air compressor, including positioning it correctly, checking the oil level and drain valve, preparing the air tank, and setting the appropriate PSI, is essential for optimal performance and safety during operation. Connecting the air hose and desired tools correctly, as well as removing excess moisture, ensures smooth and efficient air flow for your intended applications.

Regular maintenance, such as cleaning, oil level checks, inspection of belts and hoses, draining moisture, and lubrication, is vital for the longevity and reliability of your air compressor. Troubleshooting any issues promptly and addressing unusual noises or vibrations are equally important to prevent further damage and ensure safe operation.

When it comes to storage and transportation, proper cleaning, securing the power source, releasing pressure, protecting from moisture, selecting an appropriate storage space, and handling the compressor with care during transportation are key considerations to protect your investment and maintain its condition.

In conclusion, using an air compressor can be a valuable asset, but it requires responsible usage and maintenance. By following the safety precautions, understanding the components, setting up and operating the compressor correctly, utilizing air tools and accessories effectively, conducting regular maintenance, and ensuring proper storage and transportation, you can maximize the benefits of your air compressor while ensuring safety and longevity.

Remember to always consult the manufacturer’s guidelines and seek professional assistance when needed. With proper knowledge and adherence to best practices, your air compressor can serve you reliably for a long time, powering your projects and tasks with ease and efficiency.

Read More: What is CFM in Air Compressor?

Frequently Asked Questions (FAQs) about How to Use a Air Compressor

What is an air compressor?

An air compressor is a mechanical device that converts power, typically from an electric motor or an engine, into compressed air. It stores pressurized air in a tank and releases it in controlled bursts for various applications.

How does an air compressor work?

Air compressors work by drawing air into a chamber, where it is compressed and stored in a tank. When the compressed air is released, it powers tools and equipment. The process involves a motor or engine driving a piston or a rotary mechanism to compress the air.

What are the types of air compressors?

There are several types of air compressors, including reciprocating air compressors, rotary screw compressors, centrifugal compressors, and scroll compressors. Each type has its unique design and application suitability.

Are air compressors safe to use?

Air compressors can be safe to use if proper safety precautions are followed. It is important to wear appropriate personal protective equipment (PPE) such as safety glasses and ear protection, ensure proper ventilation, and adhere to recommended operating procedures to prevent accidents and injuries.

How should I maintain my air compressor?

Regular maintenance is crucial for the proper functioning and longevity of an air compressor. This includes checking and changing oil, inspecting and replacing filters, draining moisture from the tank, and lubricating moving parts. For specific instructions, refer to the maintenance guidelines provided by the manufacturer.

Leave a Reply